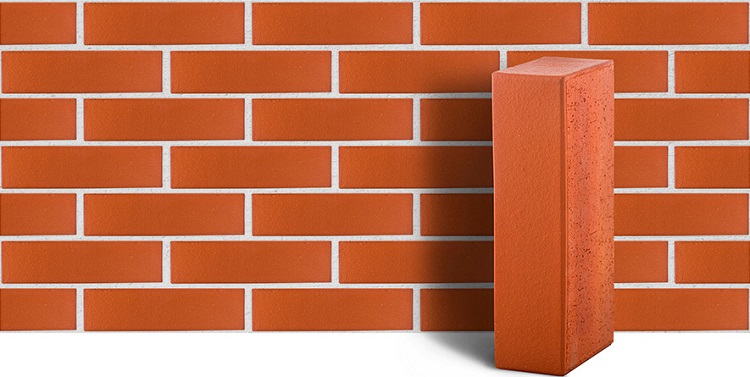

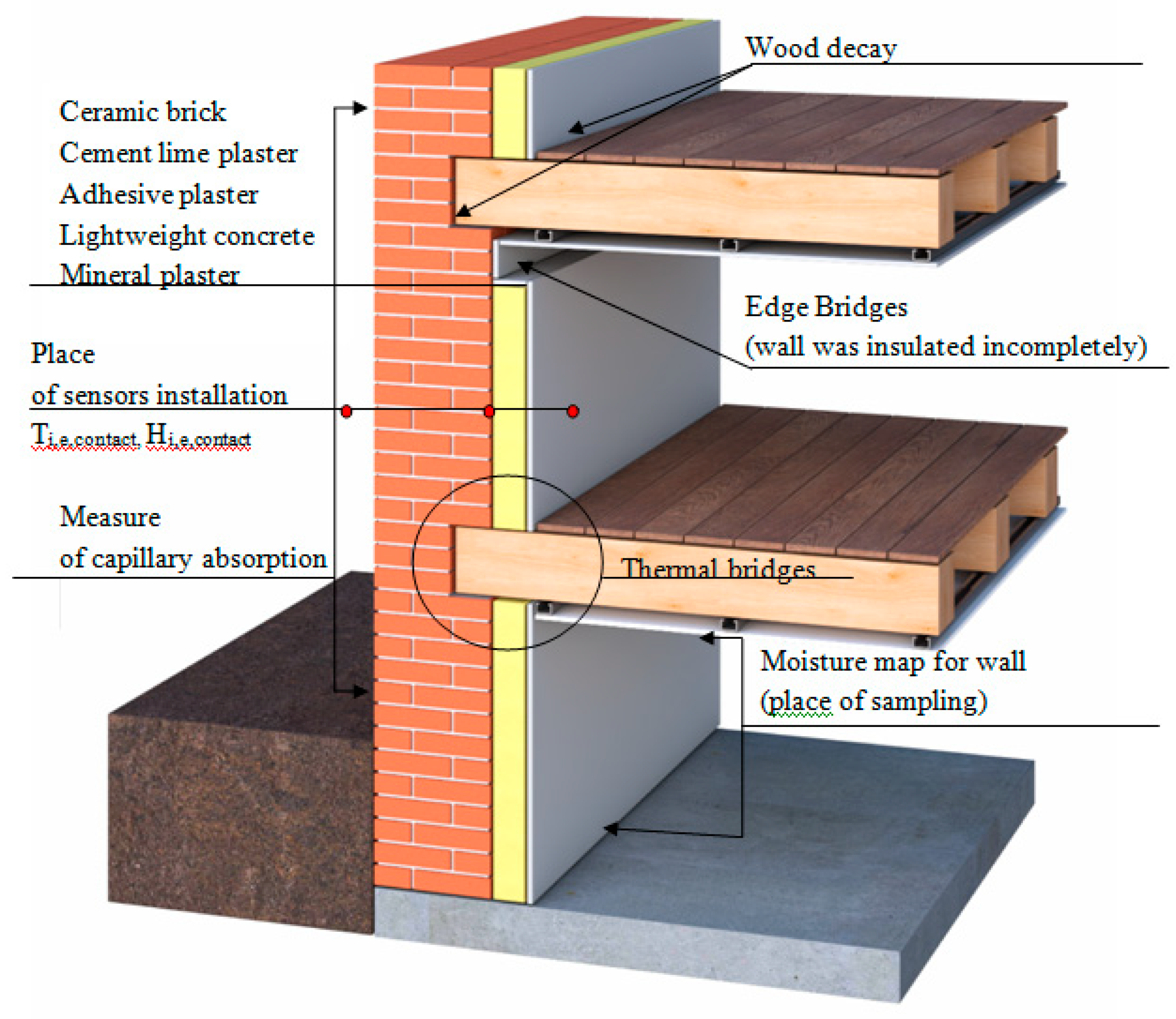

For example a brick wall has higher thermal mass than a timber framed cavity wall so it will absorb more heat than a timber framed wall of the same thickness.

Ceramic brick heat capacity.

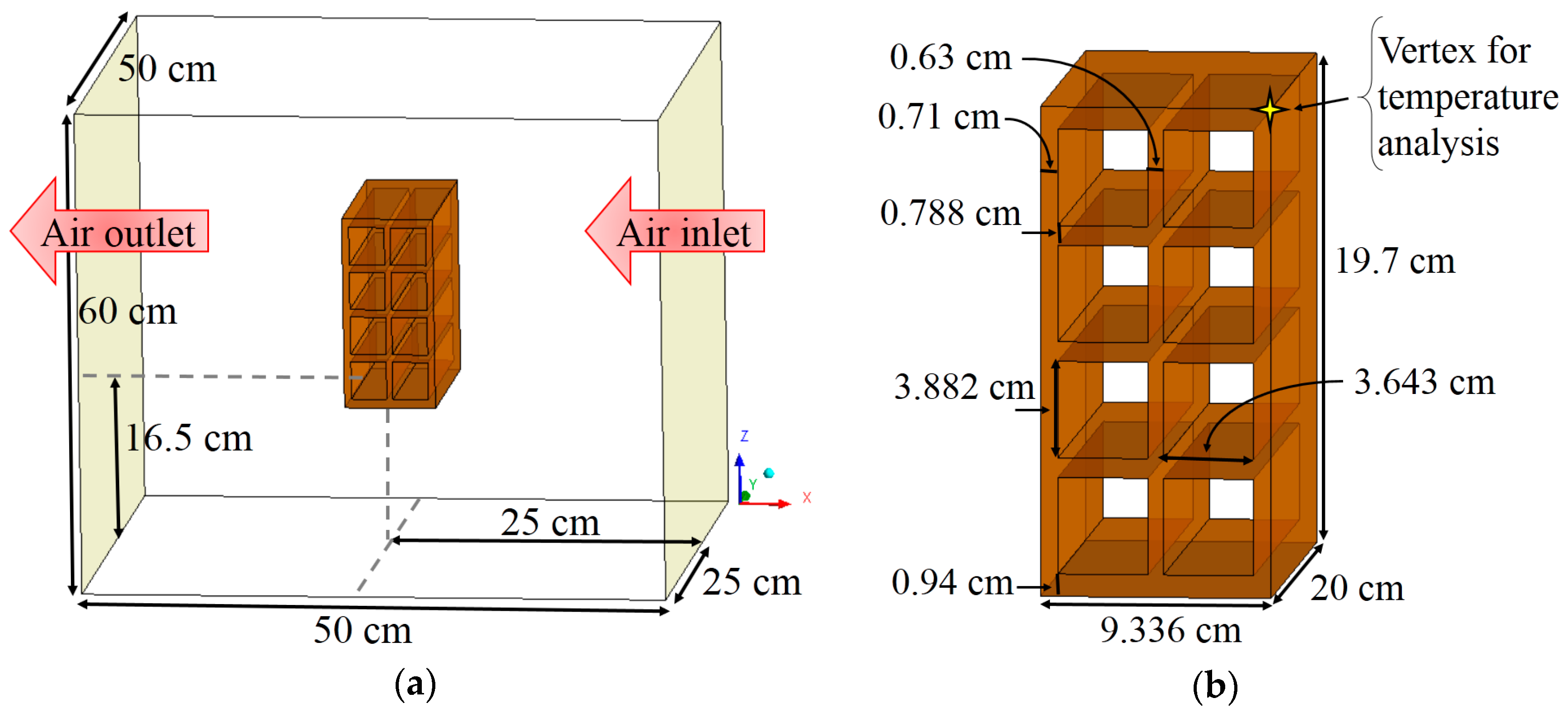

Honeycomb ceramic regenerator brick honeycomb ceramic regenerator are mainly made of cordierite mullite cordierite corundum mullite corundum and silicon carbide which has many significant advantages such as low heat expansion high specific heat capacity high specific surface area low pressure drop good thermal conductivity good.

Electric heating of a mass electric heating of an object or mass energy supply and temperature change.

Where w is stored heat in kj sq m r is bulk density of brick in kg cu m cpm is mean specific heat of the refractory bricks between the temperatures t1 and t2 in kj kg k s is wall thickness in meters t1 is the inside temperature of furnace wall in deg c and t2 is the external temperature of the furnace wall in deg c.

Brick densities densities of common types of bricks.

For products from clay and ceramics this indicator ranges from 0 7 0 9 kj kg.

Comparison with other materials.

Ceramic materials properties physical properties of ceramics.

Calculate the temperature change when 400 kj of thermal energy is transferred to a 3 50 kg brick.

Heat capacity the heat capacity of a substance is the amount of heat required to change its temperature by one degree.

The silicate brick gives indicators of 0 75 0 8 kj kg.

.jpg)