An alumina ceramic femoral head is a good bearing material because it is the smoothest material and therefore possesses the lowest wear properties low abrasive linear and volumetric wear.

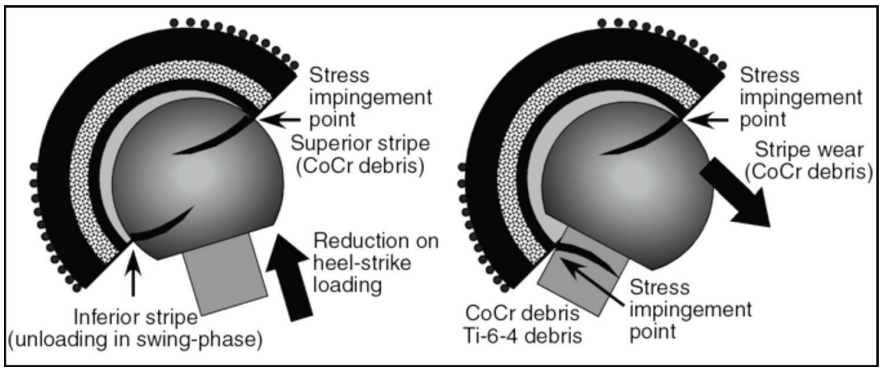

Ceramic femoral head wear.

A ceramic cup can not incorporate.

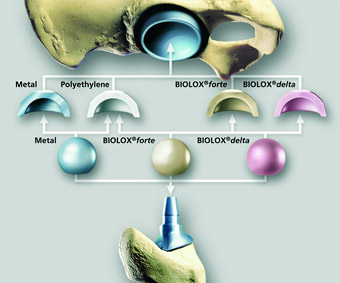

The biolox delta option ceramic head features a titanium neck sleeve designed to allow surgeons to utilize a ceramic head in either primary or.

The wear rate of ceramic on ceramic is virtually zero 0 07 μm year and even the few particles generated are completely inert.

Ceramtec is in the early stages of providing adapters to fit over a used trunion thus providing a defect free taper for a new ceramic head and the ability to retain a well fixed femoral component.

A larger sized femoral head is less likely to dislocate but will normally cause more wear.

Low wear with multiple liner options.

But with oxinium femoral heads those risks are history.

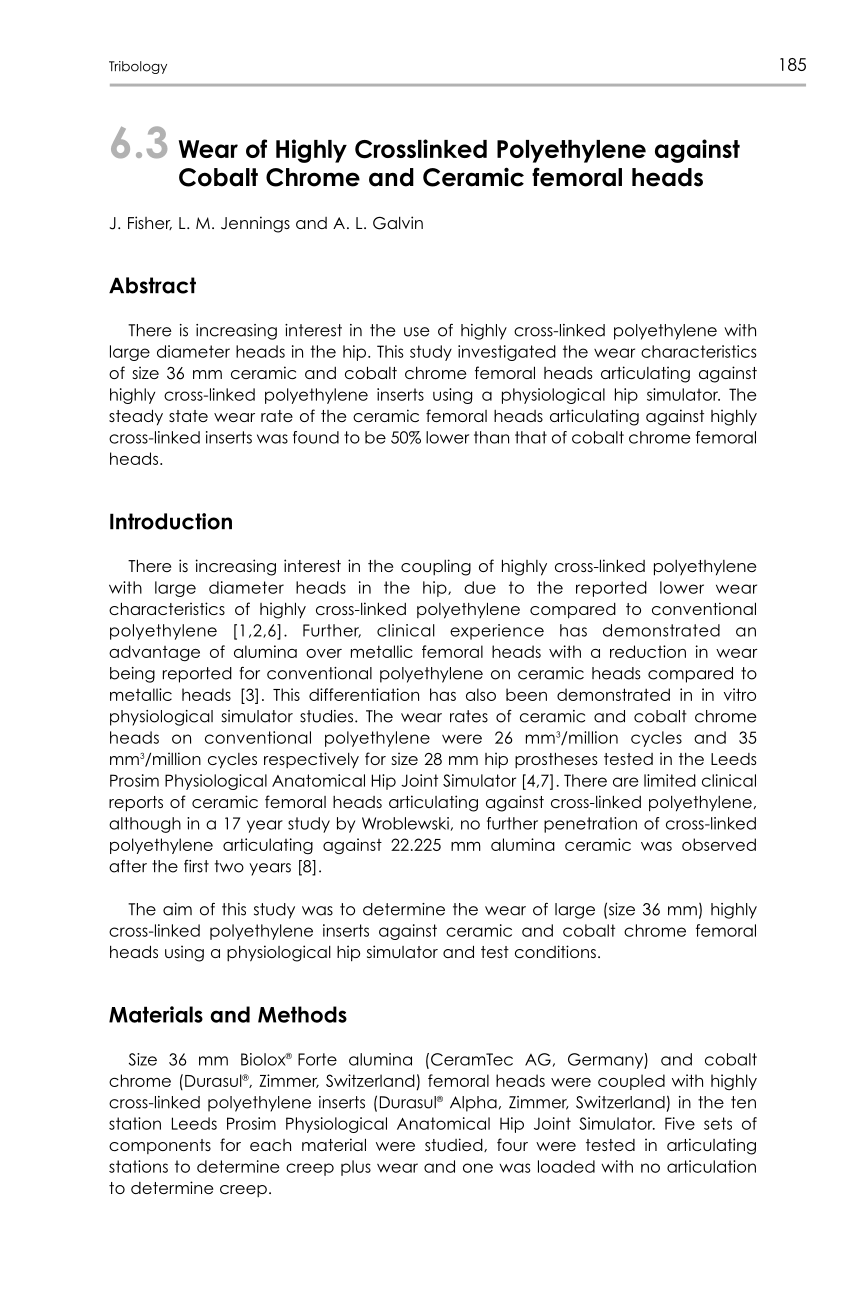

He noted previously published studies have shown.

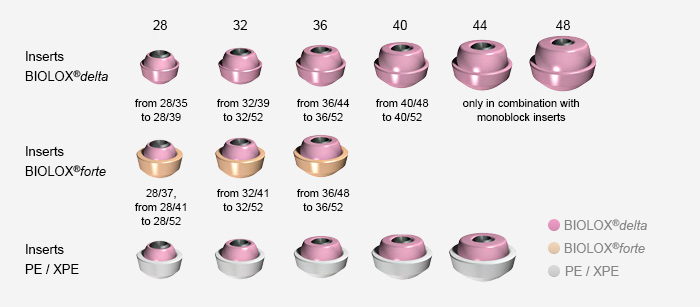

New generation of ceramic biolox delta can be used in order to produce large size ball heads d32 36 and 40 mm.

Ceramic materials have been used for tha with better clinical results compared with conventional metal on polyethylene articulation.

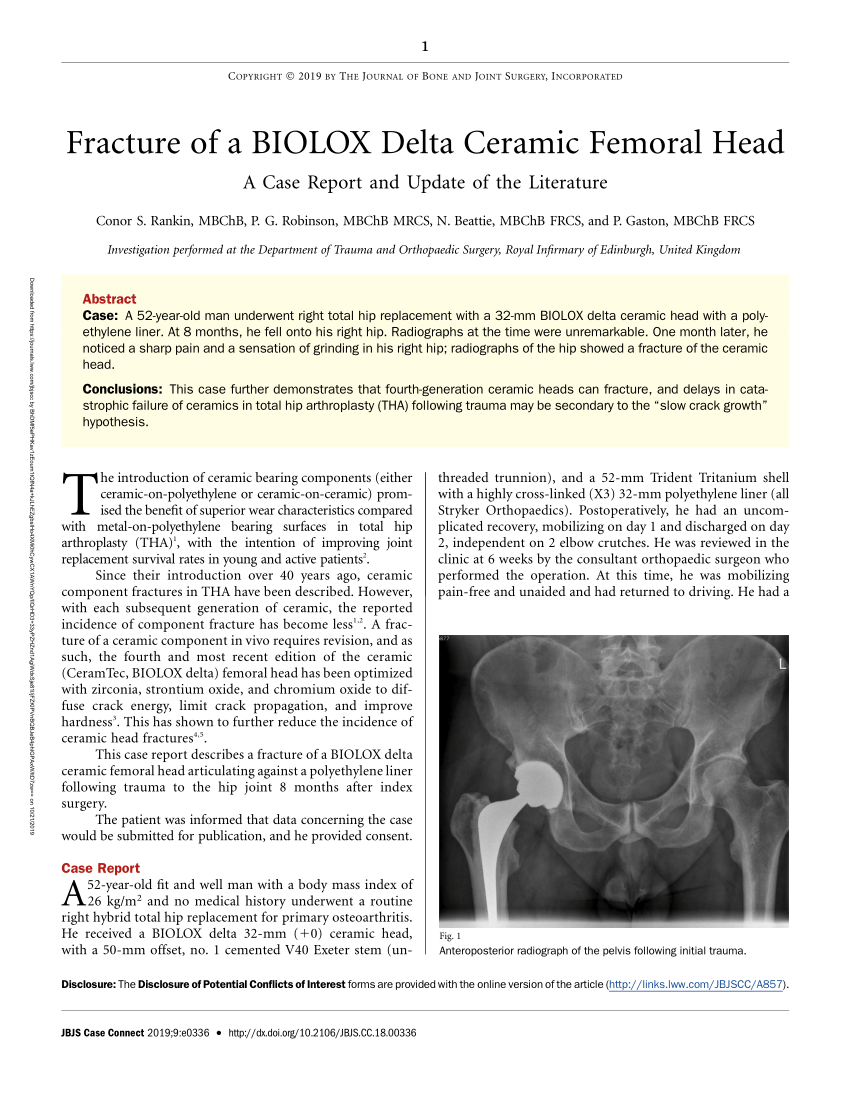

1 however there is a concern about ceramic head fracture therefore ceramic head with polyethylene liner has been introduced.

With the very low rate of wear associated with ceramic implants particularly ceramic on ceramic the surgeon is free to use a larger head and thus reduce the risk of dislocation.

P biomet offers both the biolox delta and the biolox delta option ceramic femoral heads.

Ceramic hip replacement disadvantages.

Less wear more options without the risks even the best cobalt chrome and ceramic femoral heads come with the risks of wear or breakage.

1 2 6 ceramic on ceramic articulation has the lowest wear rate among various articulations.

Our results are slightly lower than previously reported wear of ceramic and metal heads on hxlpe bearings which has been in the range of 0 012 0 067 mm y 22 29 32.

The body mounts.

Oxinium technology combines the strength of metal with the smoothness of ceramic to offer the benefits of both without the risks.

The retrieval analysis of the fractured alumina matrix composite ceramic head revealed an extremely wear resistant surface.

The fracture rate of ceramic biolox femoral heads are 0 026 for first generation alumina 0 014 for second generation alumina and 0 004 for femoral heads manufactured after 1994.

After 3 months and up to 5 years there was very little penetration of the femoral head into the liner in both groups.

The biolox delta component is a traditional one piece ceramic head indicated for primary hip arthroplasty only.

Larger ceramic ball heads.

When a larger ball head is used in a wear couple it allows to obtain an increased range of motion and stability for the patient or to reduce the risk of subluxation.