Here at cj tools mouldings we are going to look at the advantages and disadvantages of this process.

Ceramic injection molding advantages and disadvantages.

For a newer machine it could range from 375 000 to.

Advantages of plastic injection molding 1.

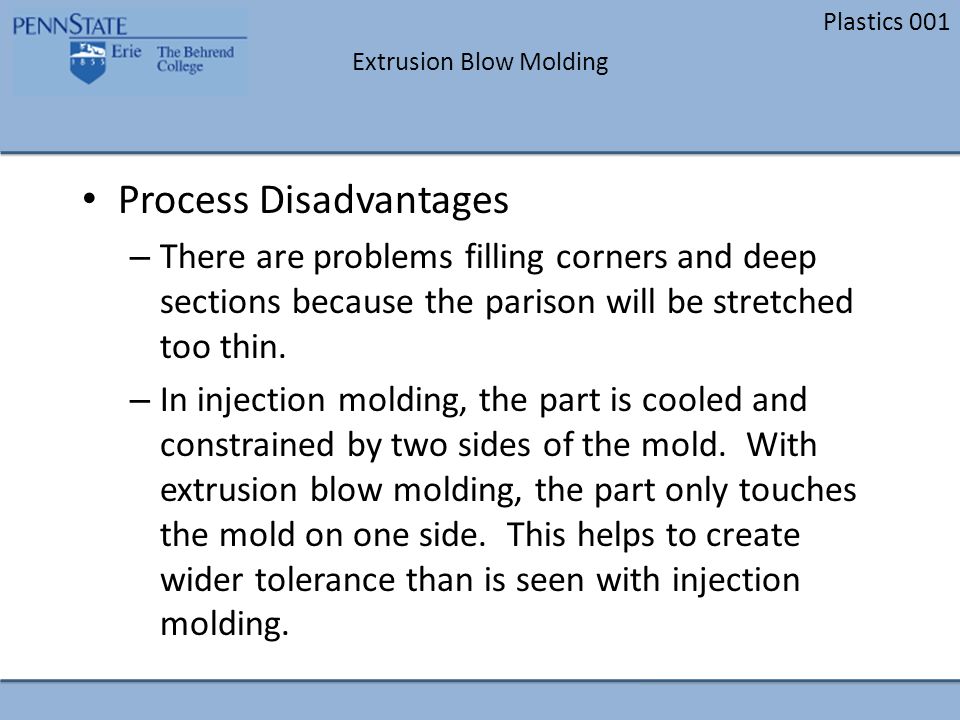

Even though there are a lot of advantages to injection molding there are some minor disadvantages as well.

From ceramic powders parts can be realized that meet the highest technical demands and aesthetic standards.

High initial tooling cost.

Advantages include the possibility for three dimensional design high dimensional accuracy and high surface quality of the parts.

Injection moulding is one of the most widely used manufacturing processes in the world today.

The examples of ceramic materials are.

Plastic injection molding is such a precise method that it can manufacture almost any type of plastic part.

As already mentioned in our injection moulding guide there s a high cost to entry to get a tool made for injection moulding.

If you look around you there are probably hundreds of injection moulded parts everywhere you look.

Disadvantages of injection molding.

Ceramic injection molding cim is a method of thermoplastic shaping.

Disadvantages of injection moulding.

If you re planning on making it yourself you ll need an injection moulding machine and the skills to run it which can also be pretty expensive.

The benefits of injection moulding.

A used injection molding machine can cost anywhere between 5000 and 50 000.